On the way up again, we followed the same route as we had come down the night before. The slack tide at Seymour Narrows was at 02.00 hrs. in the morning and thus I was on the bridge between midnight and 7 am while we were going through the various narrow patches on this run. Although the whole area was having little wind, the direction of the wind that was there was just having the right angle to blow West to East through Johnstone Strait and that created a funnel effect. Causing the wind to increase from 5 knots to about 21 knots. Unusual but I did not mind as it kept the low clouds away. In the middle of the Strait (near Kelsey Bay and Earl Ledge) the mountain ridges widen a bit, causing the winds to diminish in velocity and promptly the white wall started to build up again. Once the mountains were back in line again, the wind picked up and the white wall lifted. For a cruise ship captain, wind is normally your enemy but sometimes it works in your favor.

By 09.30 hrs. the Canadian pilots were off, and we sailed all by ourselves up the Canadian coast towards Ketchikan. We will be there by 07.00 tomorrow morning, and as the weather is still holding, it should be a dry, maybe even sunny day.

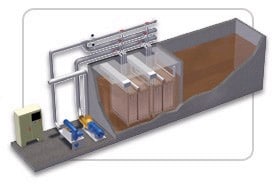

With a quiet day at sea, I get the chance to throw in one of the functions we have on board into the blog. I did a few last contract and as there are lesser known functions here we go. One of the newer positions on board is the function of Zenon engineer. Official it is called AWWP = Advanced Waste Water Purifier Engineer but that is too much of a mouth full, so we call him/her after the name of the filtration plant he/she is looking after.

Simple diagram of a Zenon plant lay out.

Simple diagram of a Zenon plant lay out.

On the Statendam we have a Zenon waste water purifying plant. Similar to what there is ashore, only more compacted. It restores everything back to 100% drinking water quality although we do not re-use it as such. About 15 years ago, the technology for waste water purification had advanced enough that fairly compact machinery could do the job and thus it became feasible to put them on board the ships. As Holland America always tries to be ahead with these sorts of things, they arrived quite quickly on the ships.

The heart of the plant, the membrane sheets.

The heart of the plant, the membrane sheets.

The system, although technically very advanced is quite simple in principle. All the waste water from the ship is pushed through a tank system with membranes in it, which filter out all the particles in the waste water. The left over fluid is filtered once again for metal concentration and acids until the final fluid achieves drinking water standards. As Health Organizations such as USPH/CDC are not convinced that the treatment plant will always work 100% we do not have permission to re-use the water so we pump it overboard. This water is called permeate. (Permeate means in English, to flow through, penetrate and/or fill a space, but not saturate it; like the smell of onions filling up a kitchen but the smell does not stay, when you open a window)

The filtered out solids go to another treatment tank that is full of bacteria. The Little critters love this stuff and eat it all. These bacteria then start to multiply and fill up the tank, but the result is that everything that was once waste has now been changed into organic matter. Every few days, we reduce the amount of bacteria by pumping an amount overboard. So even the fish have a good day.

To ensure that the system remains compliant with the standards, we get outside “samplers” on board who take samples from the tanks and then analyze them ashore. If the outcome is good we get an endorsement to our certificate and we can continue to use the system. This sampling happens on a monthly basis. As it is such a critical piece of equipment and we have to ensure high standards at all times, we have one engineer whose full time job it is to keep the system (and the little critters) happy.

It is really a great system. It saves nature as no waste water is pumped into the environment and we do not need extra holding tanks to keep it all onboard. The plant takes up the space of about eight standard car garages, stacked into blocks of four and luckily most ships had room for that in the engine room so it was possible to retro fit existing ships.

September 11, 2013 at 1:00 am

One more brilliant explanation, Captain! Not difficult to understand without getting into too many details 🙂 Possibly not difficult either on account of being more a subject of physics and chemistry ?

Thank you yet for your explanation of the “schat-darling” imprints on life boats . . .

September 11, 2013 at 4:06 am

Very interesting, thanks. You say the outside samplers come monthly. What happens when the ship is away from the US, for example on a Grand Voyage or the Zaandam based for the winter in South America?

September 11, 2013 at 9:37 pm

Good morning Jill,

Shore side samplers are only required in the State of alaska. For the rest of the world, our enviromental officer is authorized to take the sample and then send it off. The result is forwarded to the same authority.

Thank you for reading my blog.

Capt. albert

September 11, 2013 at 7:36 pm

Hi Captain Albert,

Have followed your blog avidly for a long time, so interesting, and am now looking forward to my 1st HAL cruise to the Pacific islands. A long way from Scotland but well worth it. Wondered who would be Captain on 14/02/14 from San Diego? Cheers.

September 12, 2013 at 5:25 am

I realize you said the created water is not used for drinking, but for the drinking water HAL does make and use, is the sodium content high? (I’ve heard people say the process either leaves a lot at sodium or introduces it – and there has been speculation it contributes to swollen ankles.) thanks-

September 12, 2013 at 9:38 pm

Good morning,

The zenon cleans the waste water and that goes overboard, it is not re-used. The evaporators make drinking (potable) water from sea water by means of evaporation. That is clean, pure water, there is nothing in it, it comes close to distilled. Then we treat it with chlorine as per USPH requirements and then it can be consumed. We also try to load local water at times, if they can provide a certificate of testing.

What is in that water, I do not know, but we leave the minerals in. It is the same sort of water that you get out of the tap at home, except that we treat it again with Cholrine.

I have never heard or seen test results with sodium residuals in the ships water supply. We would not like that anyway as apart from the fact that it might affect the guests, it would also clog up our pipe lines due to sedimenting.

thank you for reading my blog.

Capt. Albert