To make us all happy on this Monday morning, the day started with a deluge. Not just a rain shower but the “skies opened, bucket variation”. The first group of us was sitting in the training room and the trainer was nearly drowned out by the noise. We are going through our First Training Program of what will be a series of trainings and drills to get proficient with the Health, Environmental, Safety and Security aspects of our work. We call this the HESS induction and it is mandatory for everybody, even for those who are part of the building team. It seems peculiar to have to listen to a Fleet Trainer who explains what you have just explained to him a few days before. But that is the way the law works and what the auditors want: a list with all names and signatures. Future trainings will be job specific but all the crew has to go through this initial HESS induction program before they are even allowed to work on board. Normally they do this when they join the ship in the home port and then it is split in two parts. One part to do before they are allowed to work and the 2nd part within 24 hrs. when safely feasible. Now we have the luxury to do it shore side and with a bit more time on our hands and so we run with it.

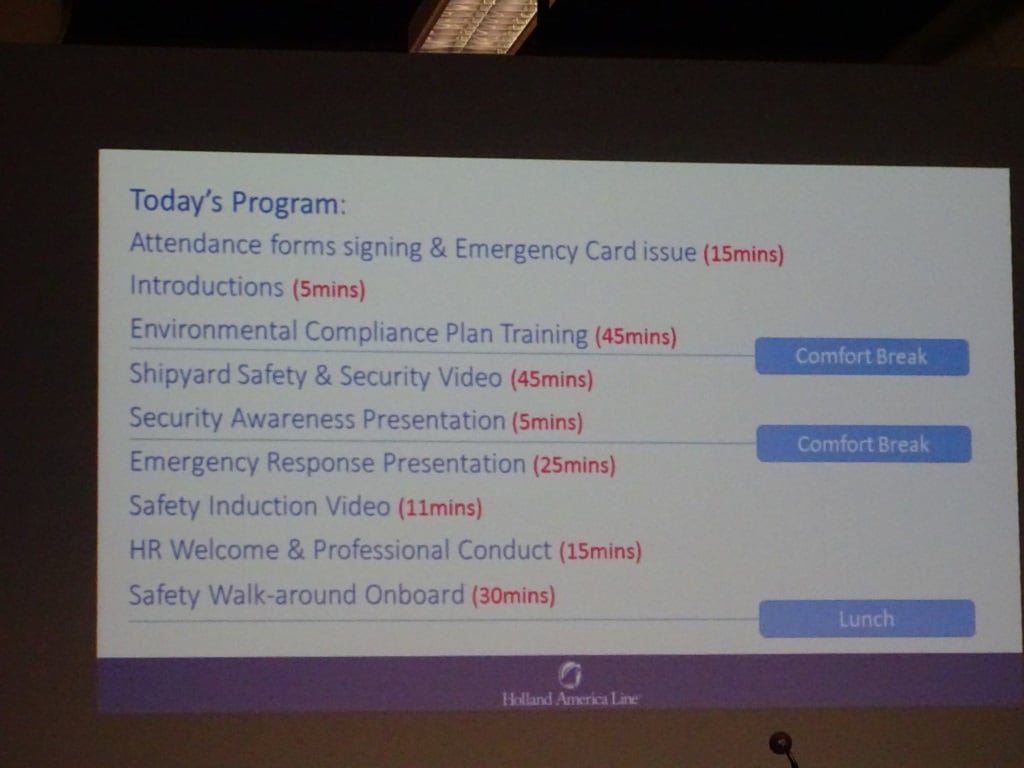

The was the program for today. What happened to the days when being told where the bridge and your cabin was, was all you needed to start working ?

While walking from the training center to the ship I saw this scene. A gigantic hydraulic jack up truck moving completed sections of a ship’s hull. As far as I know this steel is for the next Costa Cruise ship that is in the planning and her construction will start as soon as the Carnival Panorama moves out of the building dock. Ships are nowadays built in modules and sections and thus the yard can already construct part of a ship while it is not ready yet for the actual building. Sometimes new sections are even coming in from other yards (on barge) if there is space in their schedule and eventually all these building blocks are welded together as one giant jigsaw puzzle.

Moving a complete deck section for a future ship.

On the ship we are not looking at a giant jigsaw puzzle, it is more a puzzle with a lot of very small pieces that have to fill the gaps as the larger part of the puzzle has been completed. Therefore we see very little welding on the ship anymore but an awful lot of painting the large sections of bare steel and small touch ups in area’s where the paint was damaged. And then the fitting out continues. Sheets of Formica covering walls are put in place, deck coverings are being completed and sanded and a lot of remedial work is going on, there where the hand over inspections have uncovered details which are not yet up to standard.

Electricians installing the ceiling lights above the Shop Display cases in the Jewellery Shop.

As the ships nowadays depend on electronics, the number of service engineers in connection to this are increasing by the day. There were of course the electricians who installed the wiring and the operational panels on the Bridge and the Engine room but now we have the teams coming who will install the TV’s and the monitors and the computers and will make the network work in such a way that we can use it all before we leave the shipyard. And then more and more lighting is being installed. Nearly all of it LED lights, lights that do not get warm and also use very little energy.

All good for the fuel consumption as the company is forever focused on reducing our carbon foot print. We think we can still do a lot more than we are doing now but it all depends on the technology available; technology that we incorporate in a new ship whenever possible. Compared to the old steamships from the 70’s we have gone down by about 150 % in fuel consumption or so, but the Nieuw Statendam uses the same amount of fuel on a daily basis as the Nieuw Amsterdam from 1983; while the Statendam is 60,000 tons bigger and carries double the number of guests. One item that helps a little bit, but every little bit helps, is a Hotel lock in the cabins. This means that you insert your cabin key in a card reader and only then the lights in your cabin go on. When you leave pull out the key and all the lights go out. One cabin does not make much of a difference, but a 1000 cabins, day in day out, in the course of a year does make a difference.

the Dining room chairs have arrived. As soon as all the finishing touches have been completed on the lower level all the chairs will be moved in position and the table linen will come out.

More and more stores and inventory is coming on board. Today the Hotel Department was loading frozen and non-frozen stores which will be needed as soon as the catering on board begins but also chairs and related arrived and the dining room now has it chairs in situ. The medical department received is first equipment and more crew cabins were prepared for 10 November when we go on board.

All this work will continue during the coming week and hopefully it will not rain as much as this morning. Although the weather gives a 40% chance of rain on average for the next two days. Luckily the temperature remains steady around 16oC /61 oF.

Although the scaffolding on deck 2 and deck 1 has not gone yet, Deck 3 of the Atrium is clear and today I saw for the first time the multi colored lighting reflecting itself in the stainless steel structure.

November 5, 2018 at 3:31 pm

Captain Albert, this continues some great commentary and photos for those of us who love construction of the ships we sail on. Continuing thanks to you for doing this and I look forward to meeting you on 5 December, 2018.