We slipped through the Strait of Bonifacio early this morning and are now enjoying a glorious sunny day at sea. And it is a smooth sea; with a gentle to moderate breeze from the North East. Things are well in the world………… at least in our world. We are sailing on a straight South West course from the top of Sardinia down to the South East point of Spain and once there we will then follow the coast until we come to Cartagena pilot station.

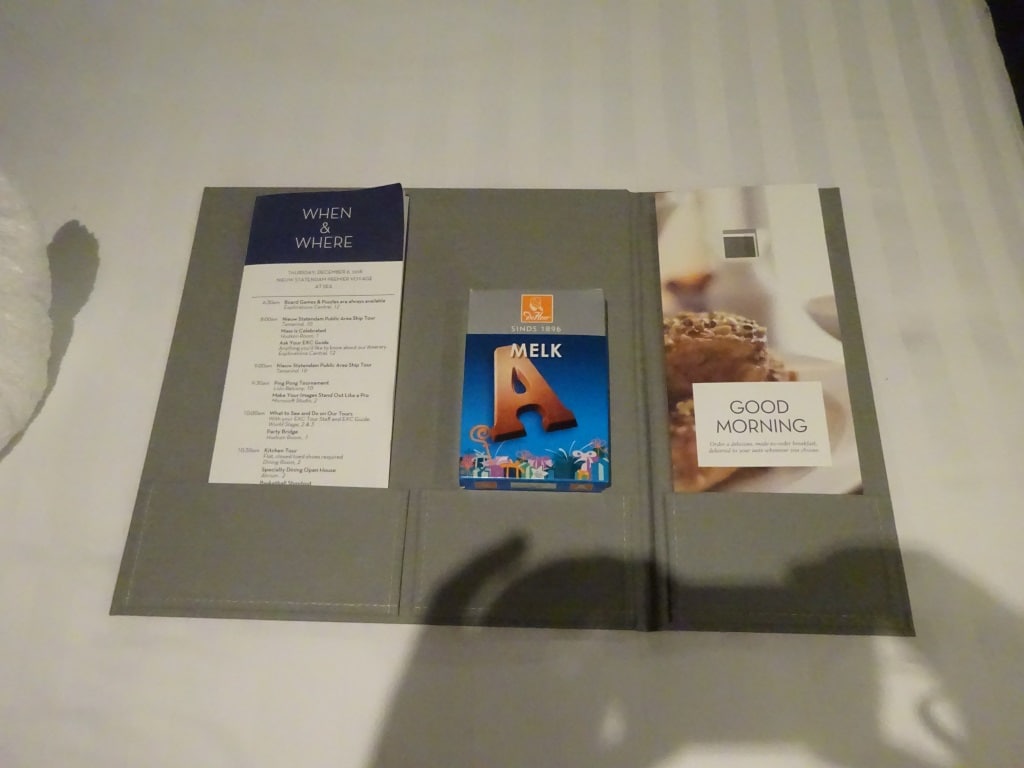

A pleasant surprise on my bed last evening after turn down service.

Last night was the “Dutch Sinterklaas” celebration in the Netherlands. Santa Claus is derived from this children’s feast which the low Dutch immigrants brought with them in the 17th. and 18th century to the USA. With all the inaugural happenings going there was not much time to focus a little bit more on this very Dutch happening but those in the know got a Dutch chocolate letter in the cabin in the shape of the first letter of the first name. This instead of the regular good night chocolate.

The ship will now settle down into it regular routine, step by step, but below decks there is still a lot of sorting out going on, mainly to get the spare parts to their correct location. When a ship is delivered it comes with a standard amount of spare parts. In the same way as a car has a spare tire. On top of that there are a lot of extra items ordered by the ships complement. Items needed to keep the ship operational. So everybody is still unpacking boxes and sorting out the right location so it can be found back when needed.

Then there are the large lists of “little things to do”. Small things; and mainly things that make the operation go more smoothly and in accordance with the company standards and practices. As an example: during stand by the sailors wear helmets. This is compulsory and these helmets should be ready for use at all times and thus not removed from the mooring deck. Helmets need hooks to be hung on. But the shipyard does not install those hooks as it is not part of the new build specification. Thus the Deck machinist will weld those hooks on the forward and aft mooring decks. Once there, the Bo ‘sun will paint them against the rust and another task will be completed. And all those small tasks run into the hundreds.

The Aft boiler room. We have two boilers one in the Forward an one in the Aft Engine spaces. Both boilers are vertical and go up three decks into the engine casing. The red part is the boiler front where the boiler is fired up. We use boilers to make steam. The man in the blue coverall is one of the engine ratings busy with cleaning up what the Yard did not clean up. At least did not clean up to HAL standards.

I spent part of my day preparing for tomorrow’s Fire drill. It is compulsory to conduct a full emergency drill every seven days and we alternate the fire part between Engine spaces and Accommodation spaces. Last week I put the crew area on A deck forward on fire and now it will be the Aft Boiler Room. The engine room is the most dangerous space on board in case of a fire. There is a lot of combustible material and fuel around (one burst fuel pipe and it gets critical) and the routines are much different than outside the engine room.

If there is a major fire in an Engine Space, and the High Fog (a sort of high pressure misting system) does not extinguish a fire straight away, then the Chief Engineer has only 10 minutes to make up his mind and to advise the Captain to release CO2. If that happens we lose power and that we like to prevent at all times. For that reason we also have two completely separate engine rooms; if one goes then we still have the other one, as each engine room has two main engines. Although we have high fog and CO2 suppression Fire teams with breathing apparatus still need to go in to assess where the cameras cannot see and remove casualties if present. Although the Aft boiler room is very spacious, fighting a fire here has its challenges. With fuel involved, the tactical approach is to drive the fire back so it can be completely covered with foam and thus smothered. But as the vertical boiler is round, there is the chance that the burning oil simply goes around the boiler and the flames appear at the other side again.

The Box -Tree in the Atrium. I doubt if the designer of the original sculpture would have thought about the fact that within a few days his/her beautiful and artistic creation would be covered under wrapped up boxes.

I had a question on the blog about if the Christmas decorations were going up? Well things are happening and our Atrium Deck 1 sculpture has disappeared under a pile of boxes to resemble a Box –Tree?? Yesterday a protective casing was built and these boxes were attached to that casing. In keeping with all the other – just different- art we now also have a -just different – Christmas tree.

Tomorrow we are in Cartagena, South Spain and it is a very nice port where the Romans had already figured out that there were worse places in the world. Weather: sunny with temperatures or 68oF / 20oC and a1% chance of showers.

December 6, 2018 at 7:47 pm

I find this “box style Atrium tree” to fit in with other photos of the art that you have posted. Very modern, but yet attractive. I rather like this Atrium tree. But, I would also hope there will be other public spaces that have a “more traditional” Christmas tree.

December 7, 2018 at 12:55 am

Great Box Christmas Tree. Nice to see Christmas decorations appearing around the Vessel. Entertainment has been exceptional.